...A Commitment to Innovation

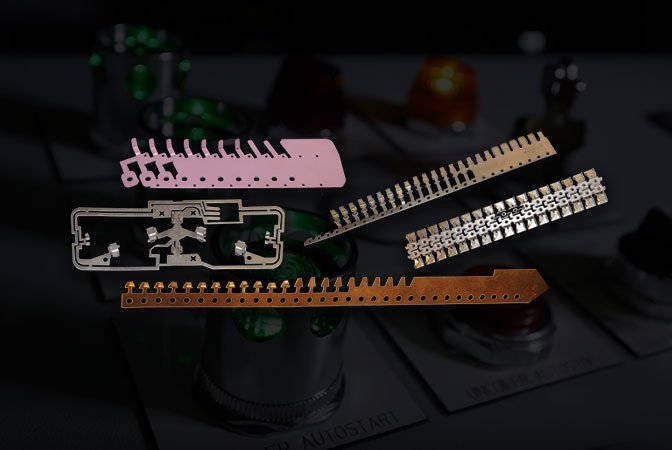

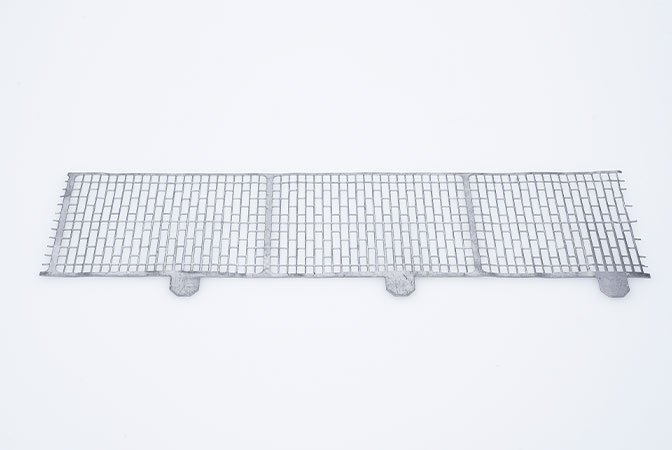

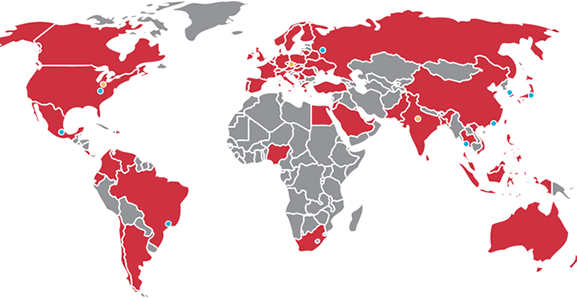

OAK Press Solutions Inc. has built a worldwide reputation for high-quality, reliable, precision stamping presses. Our commitment to the future is to provide our customers with innovative solutions in a timely manner and at a fair price.

If you would like more information about our high-speed presses, or have any questions, do not hesitate to contact us.